Teambuilding Rafting Abenteuer: Ein unvergesslicher Trip auf der Bregenzer Ach!

Letztes Wochenende stellte sich unser Team einer ganz besonderen Herausforderung: Einem unvergesslichen Rafting Abenteuer auf der Bregenzer Ach! Im Herzen des Natura 2000 Gebiets bot uns High 5 eine Kombination aus Adrenalin, Naturerlebnis und echtem Teamgeist. Eine Reise ins wilde Wasser Unter professioneller Anleitung des High 5 Teams wagten wir uns in wendigen Booten durch beeindruckende Schluchten. […]

Hämmerle Kaffee setzt auf Logistik Software von MIA Systems

„Authentischer Genuss, beste Qualität und erstklassiger Service“ – die Firma Hämmerle Kaffee GmbH mit Sitz in Bludesch investiert in die Erweiterung und Digitalisierung ihres Logistik-Centers. Im Bereich Lagerverwaltung setzt das Traditionsunternehmen auf das Warehouse Management System (WMS) der MIA Systems. Die Hämmerle Kaffee GmbH ist Großhändler, Hersteller von Instant-Heißgetränken, Spezialist für Kaffeesysteme und Dienstleister in […]

KVP-Days bei Hirschmann Automotive in Tschechien

Gemeinsam mit Servus Intralogistics war die MIA Systems bei der Digitalisierung und Automatisierung bei unserem Kunden Hirschmann Automotive am Standort Vsetín, Tschechien beteiligt. Ein Jahr nach dem GoLive fand letzte Woche vor Ort ein KVP-Meeting mit dem gesamten Projektteam statt. Hirschmann Automotive setzte bei der Erweiterung ihres Kompetenzzentrums für Spritzgusstechnik in Vsetín (Tschechien) auf das Konzept […]

Industrial UX Design: Wir gestalten die Zukunft der Intralogistik

Digitalisierung und Automatisierung stellen Unternehmen vor große Herausforderungen. Automatische Kleinteilelager, fahrerlose Transportsysteme, Cloud Software, Business Intelligence und die laufende Optimierung der logistischen Prozesse sind der neue Standard. Doch gerade bei diesem hohen Investitionsvolumen werden Benutzerfreundlichkeit und Bedienoberflächen oft vernachlässigt. Sinkende Produktivität und geringe Akzeptanz der Mitarbeiter, hoher Schulungsaufwand sowie steigende Supportanfragen sind die Folge. MIA […]

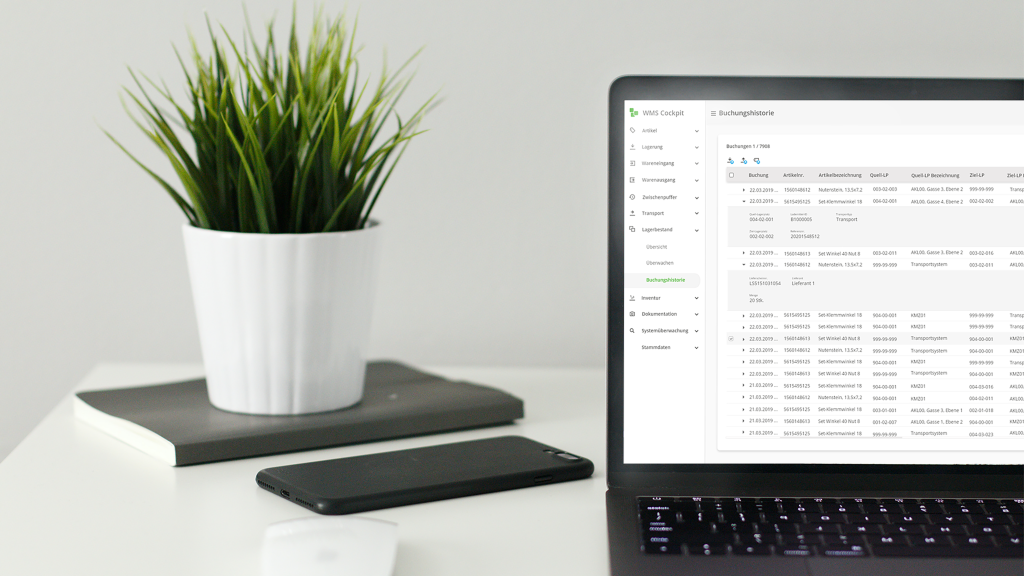

Buchungshistorie: Lagerbuchungen hochperformant anzeigen und auswerten

Lagerbewegungen im WMS generieren sehr große Datenmengen – jede einzelne Bestandsveränderung, jede Bewegung und jeder Transport wird festgehalten. Die schlaue Datenspeicherung im MIA WMS ermöglicht es Ihnen dennoch, schnell auf diese Daten zuzugreifen und diesen Datenschatz auszuwerten. Im MIA Cockpit werden diese Daten performant und transparent für Sie angezeigt. Und selbstverständlich besteht die Möglichkeit, diese Daten im BI Tool Ihrer Wahl […]

Foto Dokumentation: Zustand der Auslieferung mit dem mobilen Scanner festhalten

Mit MIA Mobile fotografieren und dokumentieren Sie auf einfache Weise den Zustand Ihrer Ware und Ihrer Sendungen – direkt in Ihren mobilen Prozessen – mit einer integrierten Kamera im mobilen Scanner. Im MIA Cockpit greifen Sie auf dieses Bildmaterial zu und besitzen die Möglichkeit, es für eine Weiterbearbeitung herunterzuladen. Einfach, in den Prozessen integriert und […]

Kral GmbH: Gewinner des Österreichischen Logistik-Preis 2020

Wir gratulieren unserem Kunden KRAL GmbH zum Österreichischen Logistik-Preis 2020! Wir freuen uns sehr, mit unserem Warehouse Management System (WMS) Teil dieses erfolgreichen und regionalen Projektes zu sein. Ausschlaggebend für das Projekt „Digitalisierung und Automatisierung in Produktion und Logistik“ war es, die Durchlaufzeit in der Produktion zu verkürzen, um so die Reaktionszeit auf dem Markt […]

PICK-BY-LIGHT: Kommissionierung die einleuchtet

Pick-by-Light ist die optimale Ergänzung zum MIA I-Point Touch für die manuelle Kommissionierung. Im Behälter werden unterschiedliche Artikel mit einer flexiblen Fachunterteilung gelagert. Vom automatischen Transportsystem (Ware-zur-Person) werden die Lademittel aus dem AKL zum Arbeitsplatz angeliefert. Mit Pick-by-Light wird durch einen Lichtpunkt sichergestellt, dass der Mitarbeiter die richtige Ware aus dem richtigen Fach entnimmt oder […]

MIA realisiert „Hands-Free Picking“ mit ProGlove

„Mark“ heißt der intelligente Handschuh des innovativen Münchner Start-Up Unternehmens ProGlove, der das Arbeiten schneller, sicherer und ergonomischer macht. Der Handschuh mit eingebauten Sensoren und Scanner passt sich der natürlichen Handbewegung des Arbeiters perfekt an und ermöglich somit ein „Hands-Free Picking“. Der Arbeiter kann sich dadurch den Griff zur Scanpistole sparen, beidhändig arbeiten und bekommt gleichzeitig […]

Effiziente Logistikprozesse bei Rosenberger Hochfrequenztechnik

Die Rosenberger Hochfrequenztechnik GmbH & Co. KG ist ein globaler Marktführer in der Herstellung von Verbindungslösungen in den Bereichen Hochfrequenz- und Fiber-Optik-Technologie. Mit rund 7.500 Mitarbeitern beliefert das Unternehmen Branchen wie Mobil- und Telekommunikation, Datentechnik, Medizinelektronik, industrielle Messtechnik, Automobilelektronik und Elektromobilität. Um den steigenden Anforderungen an Effizienz und Transparenz gerecht zu werden, hat Rosenberger das Warehouse Management […]